Olivier (my co-Founder and hubby) introduced me to 3D printing last year and I have since learnt there is much more to 3D printing than meets the eye…

3D printing is environmentally friendly! If you use PLA.

We mainly use PLA for our prints. PLA is short for Polylactic Acid, a thermoplastic polymer that is derived from renewable resources, more specifically from corn starch or sugar cane.

These are our environmentally-friendly Hexagone vase designs, unique and innovative CAD design individually printed on our customized 3D printers

The filament spools are made of a type of plastic that is not recycled by our local Council. However, a few private companies offer a recycling service for filament spools, so all is well.

Can’t find it? Print it! (or get MachineSquad to design it for you)

I have had Olivier print anything from lipstick organiser, to a hand fidget to wall mounts for Oculus Rift headsets. All in the name of Research and Development. A local business asked us to print a light louvre for LED lights used by photographers and videographers. You name it, if you can’t find it or it is downright extortionate chances are you can 3D print it for a lot cheaper. Which leads me to my next point…

3D printing is not just plastic

You can also print metal parts.

It’s not just HARD plastic

You can also use flexible filament and for example print your own shoes! (you can even print food).

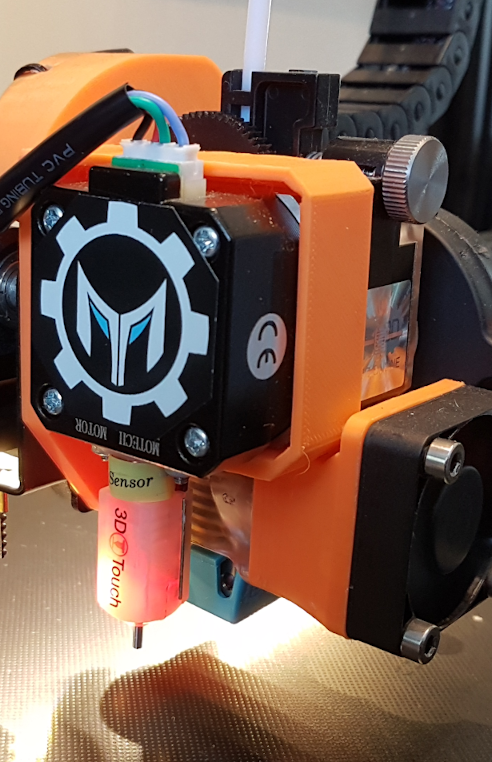

You can print your own parts

You can 3D print your own printer parts to make your printer better. There is a mixture of ready-made designs that you can borrow from specialised sites, we usually prefer to make our own.

It is not plug and play

Quality 3D printing requires a good slicer application (or two. Or three. They all do something different), accurate calibration of your 3D printer, and if the part needs to be created from scratch, 3D design skills, as in CAD skills. There is a fine balance to be achieved between the temperature of the bed, the head, the speed of printing, the speed of heating up, the temperature in the room, the level of moisture in the air, the type of filament you are using, the adequacy of the supports (you can’t print out in thin air so you need printed scaffolding for say the tail of your Pikachu, that are designed to be broken after. Pikachu is a cute one to print) and a lot of other parameters which I have to admit to not fully understand.

So as I said, not plug and play. If I had one piece of advice, I would say come to our training! More on that in the New Year…